- Pune - 411015, Maharashtra, India

- sales@aaradhyapower.com

Aaradhya Power Solutions, as leading RTPFC Panel Manufacturers in India as well as trusted RTPFC Panel Suppliers, Exporters in India, brings over 20 years of specialized experience in designing and delivering advanced power‑quality equipment. RTPFC Panel also known as Real-Time Power Factor Correction Panel or Real-Time Power Factor Control Panel (RTPFC Control Panel). Leveraging our expertise, we have earned customer trust through robust RTPFC Panels. RTPFC Panel also known as Real‑Time Power Factor Correction - which ensure optimal power factor and energy efficiency across diverse industrial settings.

These panels comply with BIS Voluntary Standard IS 16636:2017 for low‑voltage APFC assemblies, and are type‑tested by CPRI/ERDA under IEC 61439‑1 & ‑2 for switchgear assemblies. Moreover, the company’s ISO 9001:2015 Quality Management System certification underscores a commitment to consistent quality and continual improvement. Through dynamic, thyristor‑based switching with response times under 20 ms, these panels deliver fast, surge‑free reactive power correction for a wide range of industrial loads

As we are trusted RTPFC panel exporters in India and RTPFC panel suppliers in India as well as leading quality RTPFC panel manufacturers in India. These RTPFC Panels are built following BIS Voluntary IS 16636:2017 guidelines for Automatic Power Factor Correction Panels up to 1 kV and incorporate type‑tested switchgear assemblies per IEC 61439‑1 & ‑2

Key specifications include:

Types:

We at Aaradhya Power Solutions specialize in RTPFC panel manufacturers in India and RTPFC panel suppliers in India as well as RTPFC panel exporters in India, catering to heavy industries, power plants, and marine‑offshore installations. Serving clients across India and in export markets, our panels are trusted for their durability, precision control, and compliance with international standards. Over the past two decades, we have executed 800+ projects with a 99% success rate.

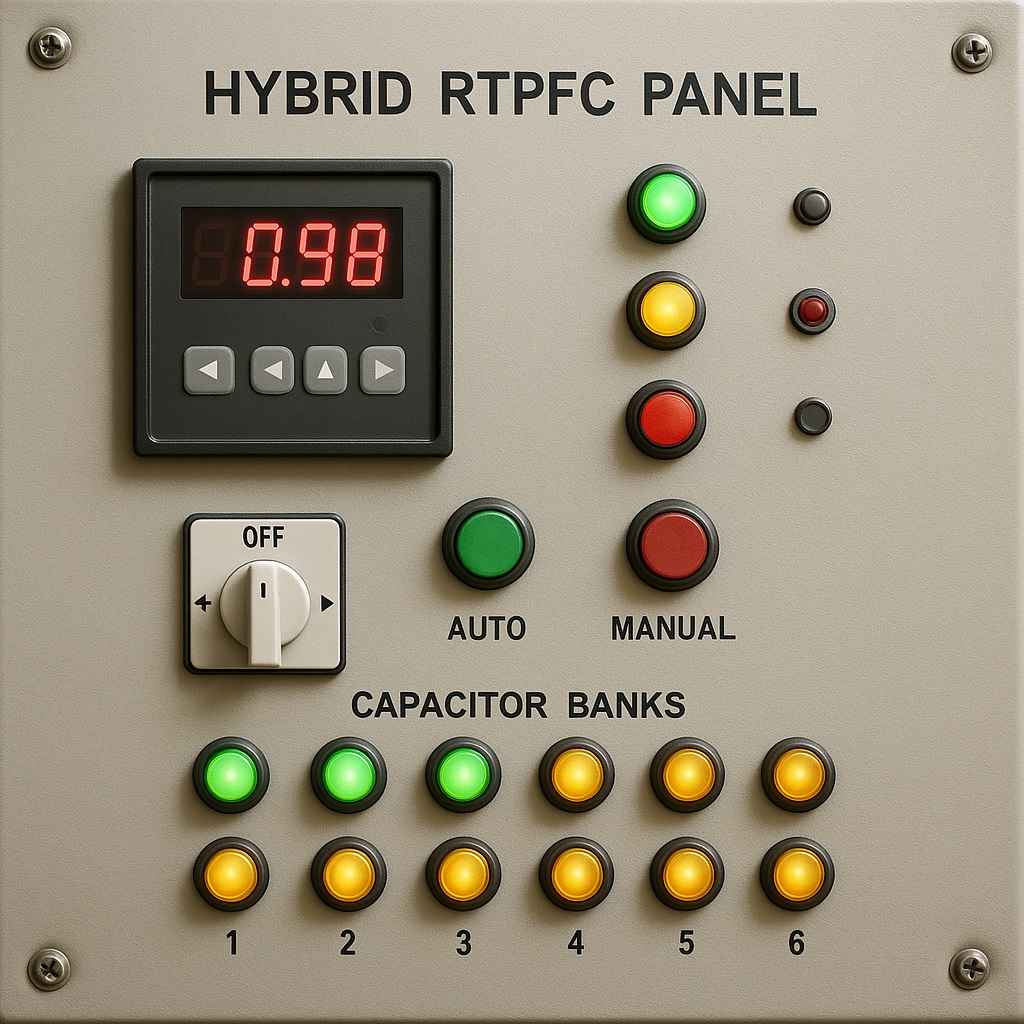

An RTPFC (Real‑Time Power Factor Correction) Panel is an automated system designed to dynamically correct power factor to near unity by switching capacitor banks in real time. These panels adhere to performance and safety specifications outlined in Indian Standard IS 16636:2017 and follow capacitor bank requirements per IEC 61921

| Specification | Details |

|---|---|

| Rated Voltage | 415 VAC |

| Frequency | 50Hz |

| KVAR | 100 KVAR |

| Steps | 12.5 KVAR, 25 KVAR, 50 KVAR, 75 KVAR |

| Capacitor Voltage | 480 VAC |

| APFC Relay | 3CT Operated with inbuilt multifunction meter |

| Switching | Thyristor Switching Modules |

| Protection | HRC Fuse/MCB/MCCB/SFU |

| Incomer | MCCB/ACB/SFU |

| Cooling | Forced using thermostat-controlled fans |

| Enclosure | Fabricated using 1.6 mm / 2 mm thick CRCA sheet |

| Cable Entry | Top/Bottom |

| Origin | Made in India |

These panels use zero-crossing thyristor switches to activate capacitor banks. The switching occurs precisely at the zero-voltage point of the AC waveform, ensuring ultra-fast and clean engagement of reactive power compensation without electrical surges or transients.

Key Features:

Best For:

These panels use electromechanical contactors (often vacuum or heavy-duty variants) to switch capacitor banks in and out based on load conditions. While not as fast as thyristors, they provide reliable and cost-effective power factor correction for more stable load environments.

Key Features:

Best For:

These Panels integrate both thyristor and contactor switching technologies in a single system. Fast-response thyristors manage dynamic load changes, while contactors handle more stable, base-load compensation.

Key Features:

Best For:

These are bespoke RTPFC solutions engineered to meet unique site conditions, particularly where harmonics and power quality challenges are significant. They may incorporate detuned reactors, harmonic filters, surge protection, and advanced monitoring systems.

Key Features:

Best For:

The RTPFC Panel’s controller measures real‑time current and voltage waveforms; when the measured power factor falls below the set threshold, it instantaneously engages the appropriate capacitor bank step via thyristor switching. This closed‑loop operation maintains the power factor within ±0.01 of unity, minimizing losses and avoiding utility penalties.

For orders and technical queries, please contact:

Together, these strengths make Aaradhya Power Solutions your preferred RTPFC Panel Manufacturers in India as well as RTPFC Panel Suppliers in India and RTPFC Panel Exporters in India.

Aaradhya Power Solution is recognized as a trusted RTPFC Panels manufacturers, suppliers, and exporters in India, offering robust, standards‑compliant equipment backed by expert after‑sales support.

To discuss your requirements or request a quote, contact us today at +91 7030243444 or sales@aaradhyapower.com. Our team will guide you through selecting the optimal RTPFC solution for your application.

An RTPFC Panel is an advanced system that adjusts reactive power in real-time to maintain an optimal power factor.

The capacity depends on the load requirements and power factor of your system. Consult our experts for accurate calculations.

The three types are fixed, automatic, and real-time power factor correction.

RTPFC stands for Real-Time Power Factor Correction.